|

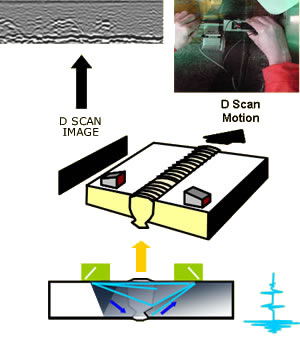

Although originally developed as an accurate defect sizing and characterization tool, Time of Flight Diffraction (TOFD) is now universally accepted as a fast and reliable method of detection. More importantly it generates an immediate dimensionally proportionate image of the integrity-critical through wall elevation, showing embodied defects in true size and location, whilst simultaneously providing an accurate profile of the back wall - making the technique also suitable for corrosion and erosion assessment. Unlike pulse echo ultrasonic methods (including Phased Array) and radiographic techniques which measure the recorded change in captured energy (which can be influenced by many factors, other than defect size) TOFD uses the measurement of time (and therefore distance) to establish the presence, position and extent of defects. Today the technique is prescribed in all major inspection codes but, as with all inspection techniques, TOFD has its limitations - most notably near surface resolution due to the presence of a lateral wave. However, the benefits of this method of testing massively out way the drawbacks.

|

|

The benefits include - · Non-invasive - requires access to one side only · Can be used on stream - remotely & at elevated temperature · Effective on thick wall material - above 6mm · Non-comparative - enables absolute size measurement · Proven POD and repeatability - with low FCR · High resolution - can be accurate to within +/- 0.1mm · Relatively insensitive to defect orientation and surface condition · Sensitive to integrity critical defects - cracks, LOF, structural damage · Fast (full) volumetric coverage - up to 10m/hr · Couplant status automatically monitoring · Immediate presentation of 'through wall' image - incl. back wall & clad interface · All 'raw data' captured & stored electronically · Code compliant and accepted by most certification bodies · Safe and non-disruptive

Specialized Inspections Co. Ltd & Testing Services has a considerable amount of experience in the use of TOFD in a wide variety of applications across many industrial sectors. This ranges from very sophisticated applications involving the detection, sizing and characterization of micro-structural anomalies on metallurgically and geometrically complex components to routine weld quality testing and back wall profiling on process pipe work, pressure vessels and storage spheres. This knowledge may be of particular value in those situations where the logistics, cost or productivity implications demand careful consideration and applications where accurate and repeatable condition monitoring is called for. |

|

Specialized Inspections Co. Ltd. provides AUT services on vessels and pipings. |

|

Time Of Flight Diffraction (TOFD) |